Welcome to Wild Plant 3D

The goal of traffic reconstruction is to reproduce motor vehicle crash situations in order to examine collision dynamics, offer evidence in court cases, and allow vehicle makers to evaluate car design. However, at the scene of the accident, it is not always clear how much information would be needed for the analysis, and crucial data is frequently lacking. The introduction of terrestrial laser scanning has made 3D documentation of accident events safer and more flexible, as data can be acquired without lane closures or traffic disruptions, and a single user may operate the equipment in full darkness or direct sunlight.

According to ANSI D (1983), there are five levels of action in accident investigation. (a) reporting, which involves the collecting of fundamental data in order to identify and classify an accident. (b) at-scene investigation, in which additional data is obtained at the accident scene in addition to the accident's outcomes, such as road and debris marks, tyre marks, and so on. (c) technical follow-up, which examines all available data relevant to an accident, such as vehicle speed and acceleration, visibility of cars, pedestrians, and other factors, and is carried out for legal and other objectives. (d) professional reconstruction, which evaluates how the road, driver, and vehicle contributed to a specific accident based on available data, and (e) cause analysis, which identifies why the accident occurred based on available data (eg deficiencies of road or vehicle design).

Clearly, data gathering and recording at the accident scene is the most important part, as they are required in all five stages of investigation indicated above. Additionally, traffic recording systems should be technologically advanced in order to offer data that is more timely, accurate, integrated, accessible, and standardised and uniform. In addition, the measurement method should cause the least amount of disruption to traffic and produce end products that can be easily converted to 2D designs. The most frequent method of measurement is 2D surveying, which involves taking measurements along and offset from a road border or centerline. Total stations and laser range finders are frequently used, however they have the drawback of disrupting traffic. GPS surveying has proven to be effective, but only in unobstructed areas. Close-range digital photogrammetric systems (e.g., Duignan et al., 1996; Fraser et al., 2004) have recently been created, which allow fast and precise data collecting but are quite expensive and hard to operate for local police and traffic.

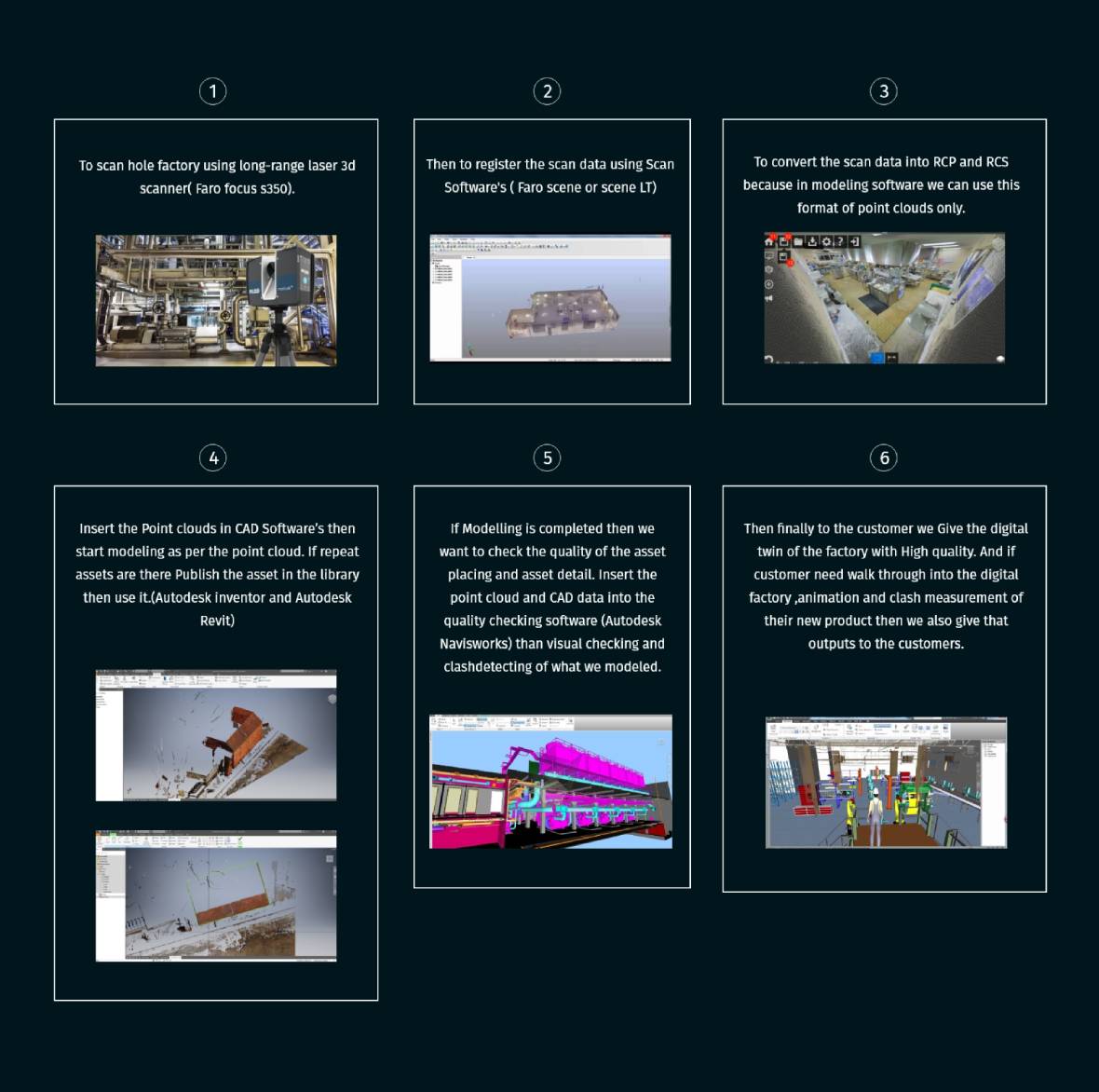

P3DM offers end to end solutions to cater