Welcome to Wild Plant 3D

The digital factory currently represents the virtual copy of future or present factory including all machines, production lines, installations and services. It provides progressive approach to complex, integrated design of production processes, systems and products of the factory.

As-built surveys using 3D laser scanning technology provide users with detailed point clouds which enable 3D modeling for diverse tasks including building reconstruction, plant layout and enhanced data presentation with augmented reality

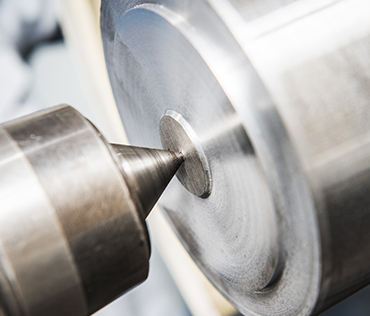

Reverse engineering is becoming a more popular method of creating a 3D model of a part without existing CAD files. Reverse engineering reconstructs classic designs and implements new ones. It can generate lost or absent design documentation and update or create as-built documentation.

In industries such as aerospace and automotive manufacturing, laser trackers and measuring arms provide a convenient way to collect measurement data and recalibrate large manufacturing robots on-site, without the need to remove them from their mounting structures.

Tool building and injection molding within the automotive, aerospace, and shipbuilding industries require a high degree of accuracy and repeatability. Laser tracker and measuring arm are portable CMMs that can perform full volumetric accuracy tests on tools and molds to ensure parts are being manufactured to the highest standard.

Movie producers and video game designers can rapidly scan and import entire movie sets, characters, and objects into various CGI platforms using 3D laser scanning technology. This captures scenes considerably faster and in better detail than traditional techniques.

Using predictive maintenance to maintain equipment, production lines, and facilities

Getting a better understanding of products by monitoring them in real-time as they are used by real customers or end-users

Component level – focused on a single, highly critical component within the manufacturing process.

Process level – this looks at the entire manufacturing process from product and process design and development, to manufacturing and production.

Component level – focused on a single, highly critical component within the manufacturing process.

Process level – this looks at the entire manufacturing process from product and process design and development, to manufacturing and production.

Component level – focused on a single, highly critical component within the manufacturing process.

Process level – this looks at the entire manufacturing process from product and process design and development, to manufacturing and production.