Welcome to Wild Plant 3D

Methods and measurement tools for dimensional quality control in the construction industry have evolved significantly in the recent time. While traditional tools like tapes, plumb bobs and gauges are still widely used, more advanced laser-based technologies are now also available that include hand-held laser distance measurers and total stations. These new measurement technologies make single measurements with significantly better accuracy and precision. However, their utilisation remains labour and time intensive, and as a result their use must rely on sampling techniques.

For example, the measurement of wall verticality using total stations is conducted by measuring only a few points at different heights along horizontally spaced vertical lines. Similarly, the measurement of warehouse floor slabs with defined-movement areas is conducted by measuring the vertical deviation from the horizontal plane at discrete points along the manually identified centre lines of the lifting equipment’s wheel paths as opposed to the entire width of the wheels or even the entire width of the equipment path.

The risk with such partial measurements is that locations presenting discrepancies larger than specified can remain undetected, leading surveyors to wrong conclusions with potentially detrimental consequences. Furthermore, it can be argued that the significant involvement of humans in the process adds the risk of manual errors. There is thus a need for approaches that enable more complete (i.e. dense) and reliable dimensional measurement, without requiring disproportionate amounts of human interaction and time. Terrestrial Laser Scanning (TLS) and Building Information

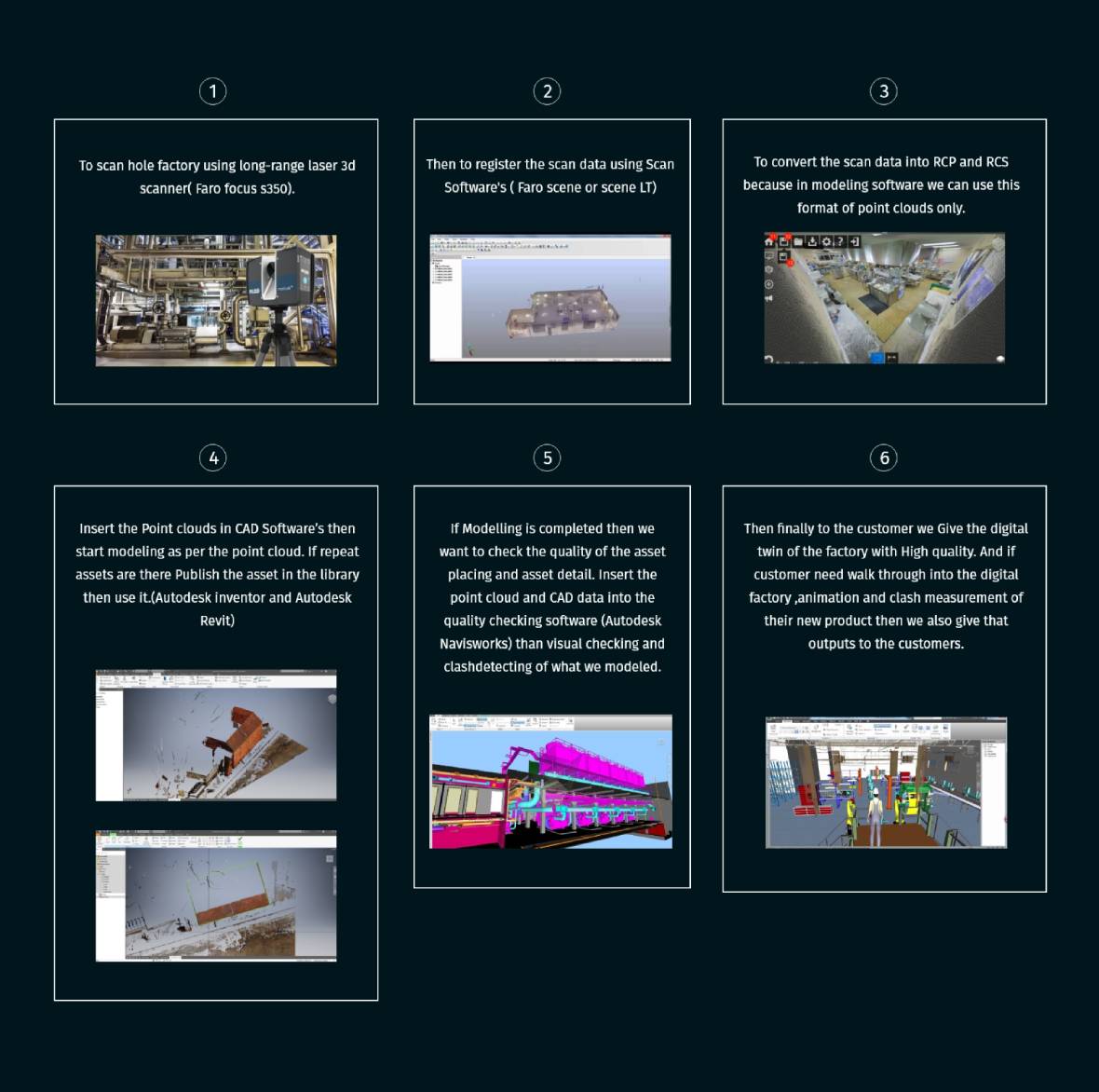

P3DM offers end to end solutions to cater